Since 1993 Productech has been designing, manufacturing and supplying coil-fed machines such as beading machines. Wherever you are, if you are in need of a beading machine, you can contact us: we export all our machines worldwide.

Let’s discover the plus of our metal beading machines and other particulars about the MONO and TRIS series:

Productech beading machine comes in two series, for better satisfying the needs of the different productive sectors:

The metal beading machineis a versatile tool designed for beading, ribbing and hemming sheets of iron, aluminum, copper and stainless steel. It is ideal for detail work and designed to make various bead profiles in sheet metal work for decorative or strengthening purposes. Beads seem easy to use, but you need to be attentive to get good looking, consistent beads.

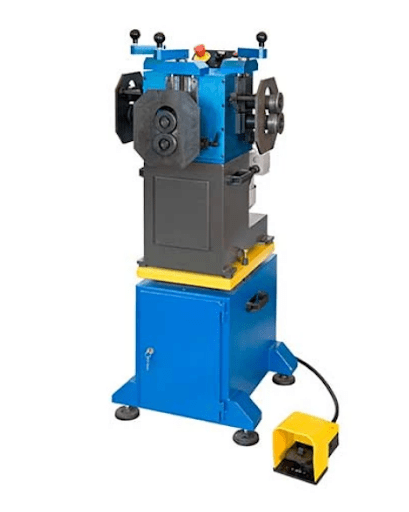

A metal beading machine is formed by an upper motor body and a lower frame with a tools-holding compartment: the two units are fixed with four knobs, for easily separating the two units in order to transport them effortlessly and for taking the minimum amount of space.

Do you want to get more information about metal beading machines?

Produtech metal beading machine models are operated by a gear motor controlled by an electronic speed variator, which allows an easy and fast progression in the rollers rotation speed (through a potentiometer); also, it is possible to make instantaneous inversions in the rollers rotation direction, because the variator automatically checks the motor acceleration and deceleration.

In addition, the use of ball bearings – instead of plain bearings – allows to achieve rollers rotation speed that is almost double in comparison with traditional metal beading machines.

On each working head, these automatic metal beading machines are equipped with holding plates of hardened steel that guide the sheet during the processing stages, preventing it from getting scratched or cut: for each working head, the holding plates can be adjusted.

The upper roller – operated by means of a manual screw lever (manual version) or a pneumatic cylinder (pneumatic version) – vertically moves on hardened guides, thus keeping parallelism with the lower roller and avoiding "scissors-like" motion.

Currently our catalogue includes four different models of beading machines in addition to several versions of punching and laser cutting machines.

The metal beading machines belonging to the TRIS series are equipped with three working heads and three couples of rollers with different shapes.

They come in two versions that differ on the base of the roller diameters:

The major advantage of these metal beading machines lies in the fact that they contribute to reducing processing time and space occupancy as just one machine is able to carry out the work usually made by two beading machines.

Both the MONO and TRIS lines are meant for several applications and sectors, among which:

The major advantage of these metal beading machines lies in the fact that they contribute to reducing processing time and space occupancy as just one machine is able to carry out the work usually made by two beading machines.

Plus, all our metal beading machines include CE marking and are delivered worldwide. The fact that every machine is customised according to the needs of the end customer ensures maximum flexibility from the point of view of loading, controls and the other production requirements.

Are you after a reliable and performing metal beading machine?

Contact us for free: we export worldwide!

The beading machines of MONO series are equipped with one working head (a couple of rollers). They present two versions, according to the rollers diameter.

The beading machines of TRIS series have a machine body rotating around a base, in order to facilitate the processes requiring roller change; this series is equipped with three working heads, and so, with three couples of rollers with different shape, allowing to make processes that are complex and require a sequence of steps (for example, hemming valves boxes, sheets hemming, tapering and joining tubes and curves, etc.).

TRIS BEADING MACHINES present two versions, according to the rollers diameter.